Calibration

For calibration videos involving the touch screen, visit http://www.supersystems.com/tech-videos.

Overview

The series 9205 can be calibrated using the Touchscreen interface. Before performing this procedure on a newly installed controller, the unit needs to be powered on for at least 30 minutes for a warm up period.

The series 9205 has three analog inputs. Each range has a zero and span calibration value. A cold junction trim value must be calibrated for thermocouple inputs. There are two analog outputs each with a zero and span value.

To calibrate an input or output, select the desired option and continue. Note – Even though the “Cold Junction” option is listed first, the inputs and outputs should have the zero and span calibration performed BEFORE performing a cold junction calibration.

Equipment needed

A certified calibrator(s) with the ability to input and read millivolts, milliamps and thermocouples is required. The appropriate connection leads are also required. A 24VDC 75-watt power supply is required.

Notes

Input 1 – terminals 31 and 32

Input 2 – terminals 29 and 30

Input 3 – terminals 27 and 28

Output 1 – terminals 24 and 25

Output 2 – terminals 25 and 26

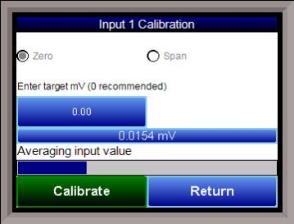

Zero Calibration - Inputs

To perform a zero calibration, click on the “Zero” option - The circle will be filled in with a dot for the selected option. For a zero calibration, the recommended value to source is 0 mV.

Click on the Calibrate button to begin the calibration.

A progress bar will be displayed along the bottom of the screen giving the progress of the calibration.

Span Calibration - Inputs

To perform a span calibration, click on the “Span” option - The circle will be filled in with a dot for the selected option. For a span calibration, the recommended value is 90 % of the full range. For example, if the range is 80 mV, then the span should be 72 mV. The recommended value can be changed by clicking on the value, and entering the new value that way.

Click on the Calibrate button to begin the calibration.

A progress bar will be displayed along the bottom of the screen giving the progress of the calibration.

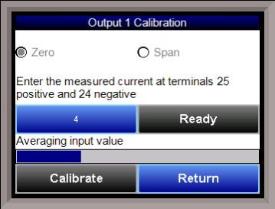

Zero Calibration - Outputs

To perform a zero calibration, click on the “Zero” option - The circle will be filled in with a dot for the selected option. When ready to start the calibration, click on the Ready button. The user will then have to measure the current at the appropriate output terminals and enter that value on the button next to the Ready button by clicking on that value button and entering the value.

Click on the Calibrate button to begin the calibration.

A progress bar will be displayed along the bottom of the screen giving the progress of the calibration.

Span Calibration - Outputs

To perform a span calibration, click on the “Span” option - The circle will be filled in with a dot for the selected option. When ready to start the calibration, click on the Ready button. The user will then have to measure the current at the appropriate output terminals and enter that value on the button next to the Ready button by clicking on that value button and entering the value.

Click on the Calibrate button to begin the calibration.

A progress bar will be displayed along the bottom of the screen giving the progress of the calibration.

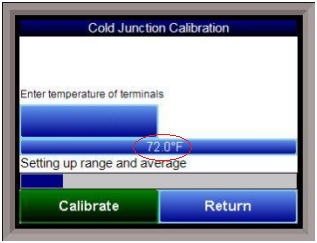

Cold Junction Calibration

NOTE: Perform zero and span calibrations (see previous sections) before following this procedure.

The “Cold Junction” option will allow the user to perform a cold junction trim on the 9205 analog input board.

To determine if a cold junction adjustment is needed, hook up the calibrator with the appropriate T/C wire attached (reference the specific input under the “Analog Input Setup” menu), then source a temperature to the input. It is best to use an operating temperature to source; for example, if the furnace typically runs at 1700 °F, then 1700 °F should be sourced to the input. Source a range of temperatures – this will help determine whether any difference in readings is linear.

NOTE: This value is NOT the temperature displayed on the “Cold Junction Calibration” menu option – rather, this is the value displayed on the main screen above set point and output.

If the displayed value does not equal the value being sourced, then a Cold Junction Calibration may be necessary. To begin, note the difference between the displayed temperature and the sourced temperature. This is the adjustment that will be made in the “Cold Junction” menu. For example:

|

Source Temp |

Displayed Temp |

Difference |

Cold Junction Adjustment |

Current Temp of Terminals |

New Temp of Terminals |

|

1700 |

1711 |

11 High |

-11 |

72 |

61 |

In this situation, the displayed temperature on the main screen is 11° higher than the sourced input. Therefore, 11° must be subtracted from the current “temperature of terminals” reading (see FIGURE). Tap the blue box below “Enter temperature of terminals” and enter the appropriate value (in this case, 61).

Click on the “Calibrate” button to begin the calibration.

After 30 minutes, verify the calibration by again sourcing a temperature to the input and checking the displayed temperature reading on the main display. It is recommended to perform this calibration check after every cold junction calibration.

Click on the Return button to close down the screen.