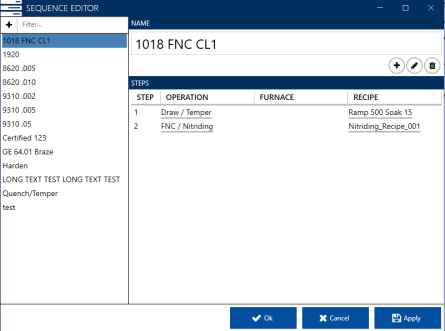

Sequence Editor

The Sequence Editor window allows you to create a series of steps (called a Sequence) that can control how a part or work order is processed through multiple operations, furnaces and recipes. The basic functionality of the Sequence Editor is the same as the Operations Editor (see p.12). The purpose of the sequence is to create consistency on the flow of a work order or part through the heat treat operations. The interface makes it very easy to apply the steps to achieve all operations. For example, if part xyz will always go through a wash, harden and temper process, it would be beneficial to create a sequence that would follow these steps. This does not have to be part specific, it can just be a consistent process used for a work order.

Once a new Sequence is created and named, use the New  button to add steps to the Sequence. Steps consist of Operation, Furnace, and Recipe assignments. Click “Save” to add the step to the sequence.

button to add steps to the Sequence. Steps consist of Operation, Furnace, and Recipe assignments. Click “Save” to add the step to the sequence.

In the example above, the 1018 FNC CL1 sequence can be applied to a part or a work order to ensure that these 2 steps are completed. The sequence can optionally assign the furnace and recipe.

To edit a step, click the Edit  button or double-click on the step in the Steps display area.

button or double-click on the step in the Steps display area.

NOTE: If a Sequence is displayed in bold italics within the list view,

this indicates that it contains unsaved changes.