4.7 Two-Point Offset

NOTE: Calibration is addressed in Section 9.

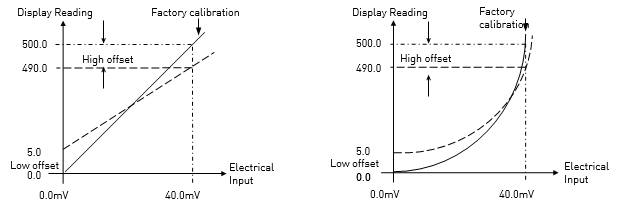

Two-Point Offset provides a method of adjusting the displayed process value to compensate for known measurement errors in a particular process or batch, without affecting the fundamental calibration of the input. Since adjustment may be required between batches, it is available in level 2.

Two point offset adjusts both a low point and a high point and applies a straight line between them. Any readings above and below these two points will be an extension of this straight line. For this reason it is best to perform this procedure with the two points as far apart as possible.

Example: Assume the controller is calibrated to display 0.0 for an input of 0.0mV and 500.0 for an input of 40.0mV. A particular process has known system errors such that the controller is required to read 5.0 for an input of 0.0mV and 490 for an input of 40.0mV.

Adjust as follows:-

|

Operation |

Action |

Display |

|

In Level 2, select Two-Point Offset (UcAL) |

1. Press |

|

|

Apply the low mV input (0.0mV in this example). |

2. Press 3. Press 4. Press 5. Press 6. Then scroll back to UcAL |

|

|

Apply the high mV input (40.0mV in this example).

|

7. Press 8. Press 9. Press 10. Press |

|

|

In Operator Level the controller will now read 5.0 for an input of 0.0mV and 490.0 for an input of 40.0mV. |

||

|

To remove the user set values |

1. Scroll back to UcAL 2.

Press 3.

Press |

|

|

In Operator Level the controller will now read 0.0 for an input of 0.0mV and 500.0 for an input of 40.0mV. |

||

until UcAL is displayed

until UcAL is displayed

or

or  to select

to select