- Phone:513.772.0060

- Address:7205 Edington Dr. Cincinnati, OH 45249

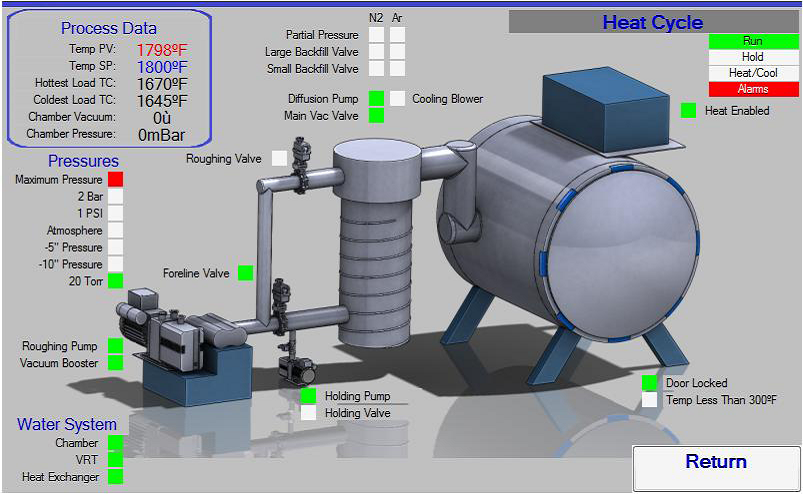

The 9220 is a robust and easy-to-use vacuum furnace recipe controller designed specifically for heat-treaters. The controller has a large full-color touch screen interface which displays temperature, vacuum data, load thermocouples, current recipe status and remaining time. The 9220 is also a paperless chart recorder, enabling real-time and historical analysis of all process variables.

Programmable Controller; 300 24-Step Recipes |

Expandable Load T/C Support |

Direct Connection to Vacuum Gauges |

Interfaces with most Vacuum Controllers |

“Outgas” Hold Alarm |

Load T/C Alarms |

Recipe Driven |

Guarantee Soak on Load and Control T/Cs |

Multiple Auto-Switching PIDs |

Video Recorder |

16 PIDs via program opcode |

3 PID sets / loop with defined temperature switch point |

T/C comparison with offset available for T/C checks |

Multiple alarms assigned to individual relays or a single relay |

“0.00” setpoint deactivates control output |

Band limits for each process variable |

Remote setpoint for third input |

| Control Loops | Temperature and Vacuum (three loops of control) |

| Analog Inputs | Three |

| Analog Outputs | Two (0-20 mA or 4-20mA) |

| Digital Inputs | Four |

| Digital Outputs | Eight relay outputs (Expandable to 16 or 32) |

| Communication Ports | One (1) – RS232 Three (3) – RS485 Ethernet |

| Display | 3.5″, 5.7″, 12.1″, 15″ and 17″ Color touch screen Video recorder with “NOTES” capability Removable storage media (948 months of data) PC interface with SuperDATA |

| Programmable | 300 24-Step Recipes Vacuum specific “opcodes” |

| Events | User Defined |

| Web Browser Enabled | Remote PC view with standard Web Browser |

| Mounting | DIN rail or sub-panel mounting |

| Power | 24 VDC |

| Product Line | User Manual | Datasheet | Wiring | Other |

|---|---|---|---|---|

| 9220 Vacuum Controller | PDF | Online | 9220 Datasheet | 9000 Series Maintenance | |

| Safety Certification: NRTL – Intertek | ||||

| General Info | Configurator Product Technical Brief | |||

| Compact HMI Product Technical Brief | ||||

| Process Automation – Industrial Heating, January 2008 | ||||

| Touchscreen Cleaning Procedure |