- Phone:513.772.0060

- Address:7205 Edington Dr. Cincinnati, OH 45249

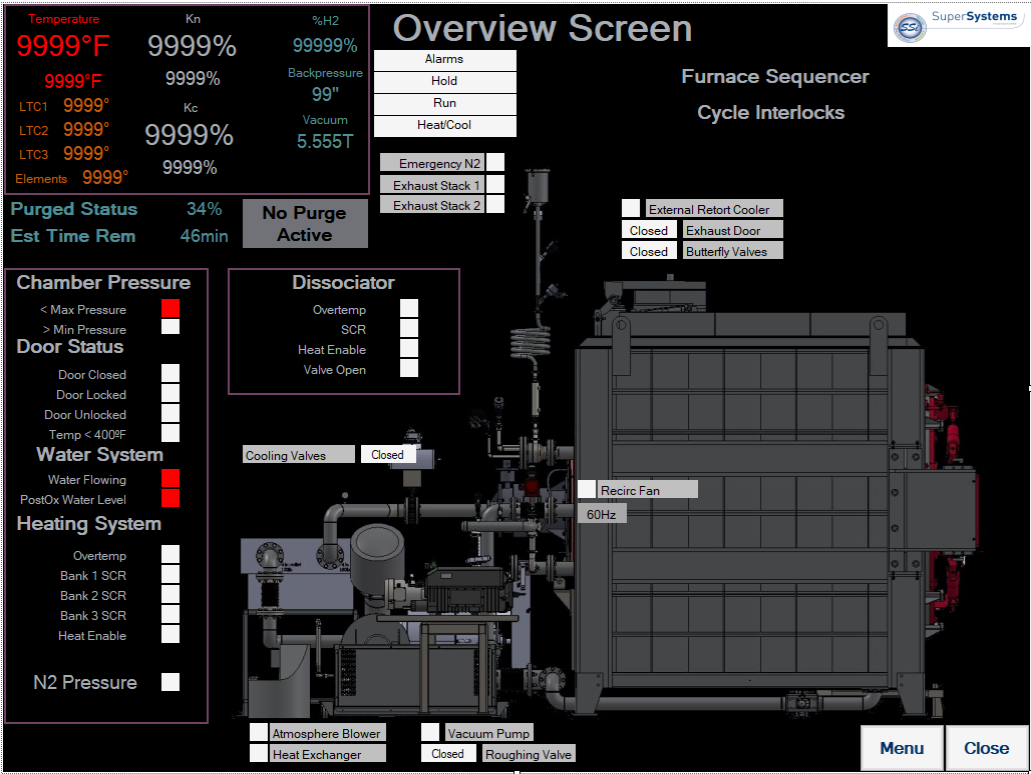

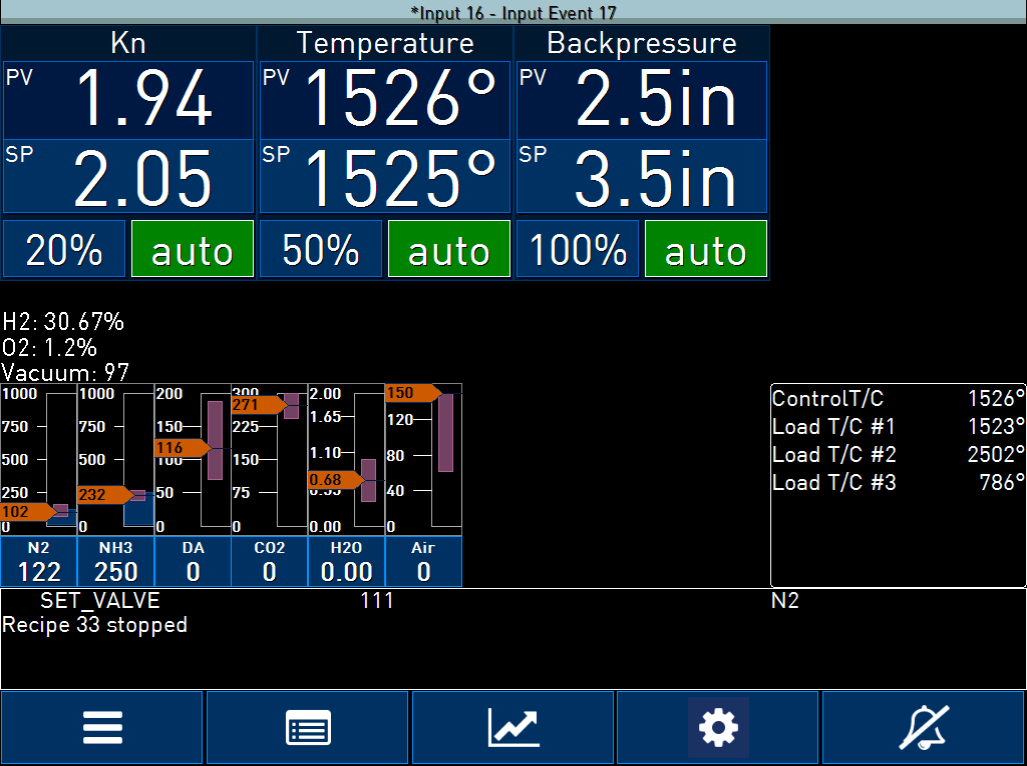

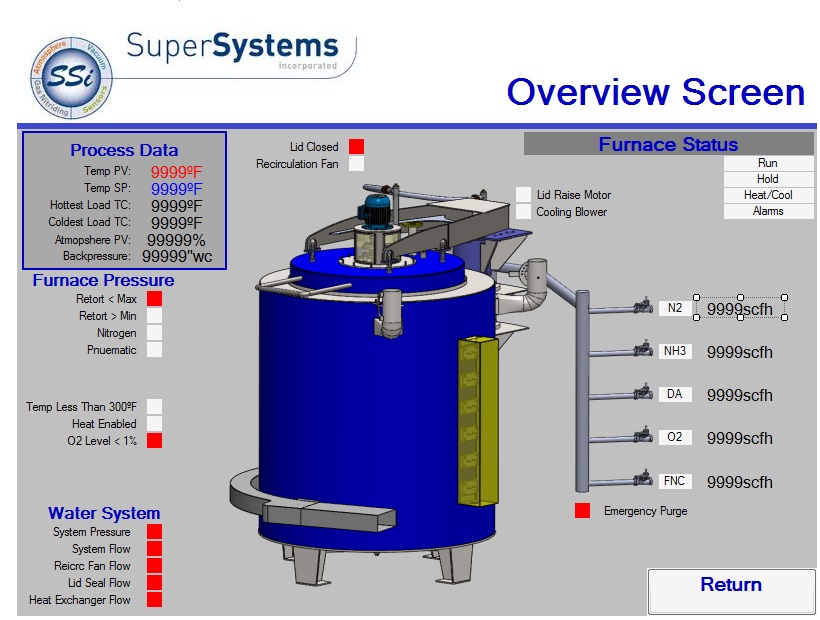

The powerful 9215 multi-loop controller provides comprehensive, intuitive nitriding and ferritic nitrocarburizing gas atmosphere furnace PID control and programming. It includes precision control loops with independent PID control for Temperature, Kn/%DA, and Kc. With cHMI, the 9215 becomes a comprehensive furnace HMI for operators and maintenance personnel.

| 16 PIDs via program opcode |

| 3 PID sets / loop with defined temperature switch point |

| T/C comparison with offset available for T/C checks |

| Multiple alarms assigned to individual relays or a single relay |

| Band limits for each process variable |

| Guaranteed soak timer based on auxiliary load thermocouples |

| Remote setpoint for third input |

| 300 24-Step Recipes |

| Flow control (N2, NH3, DA, CO2, Endothermic, H2) |

| Atmosphere measurement (Oxygen, Hydrogen) |

| Automated Back Pressure Control |

| Control of KN and % DA |

| Automatic Single and Two Stage Process |

| Precise Control of Compound Layer |

| Automated N2 Purge |

| Pre/Post Oxidation |

| Fully programmable |

| Sophisticated Programming (ramp/soak/guarantee on load temp.) |

| Control Loops | Three Loop PID controller Temperature, Atmosphere (Kn, %DA) |

| Analog Inputs | Three |

| Analog Outputs | Expandable |

| Digital Inputs | Four |

| Digital Outputs | Eight relay outputs (Expandable to 16 or 32) |

| Communication Ports | Two (2) – RS232 Three (3) – RS485 Ethernet Allen Bradley DF1 |

| Display | 3.5″, 5.7″ and 12.1″ Color touch screen Video recorder with “NOTES” capability Removable storage media (948 months of data) PC interface with SuperDATA |

| Programmable | 300 24-Step Recipes |

| Events | User-Defined |

| Web Browser Enabled | Remote PC view with standard Web Browser |

| Mounting | DIN rail or sub-panel mounting |

| Power | 24 VDC |

| Product Line | User Manual | Datasheet | Wiring | Other |

|---|---|---|---|---|

| 9215 Nitriding Control System | PDF | Online | Nitriding/FNC Brochure | Safety Certification: NRTL – Intertek | |

| General Info | 9000 Series Maintenance – Product Technical Brief | |||

| Compact HMI – Product Technical Brief | ||||

| Furnace Utilization Reporting System (FURS) – Product Technical Brief | ||||

| Configurator – Product Technical Brief | ||||

| Process Automation – Industrial Heating, January 2008 | ||||

| Touchscreen Cleaning Procedure | ||||

| 9xxx Screen Cutouts |