- Phone:513.772.0060

- Address:7205 Edington Dr. Cincinnati, OH 45249

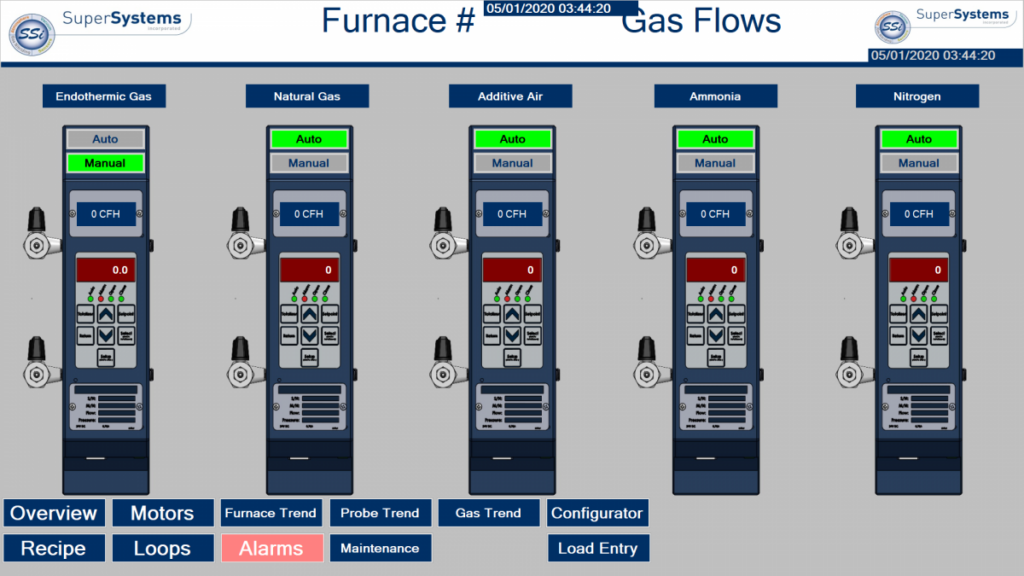

eFlo 2.0 is SSi’s newest electronic flow measurement instrument line. Like our previous eFlo models, the 2.0 line offers simple compatibility with existing controls, making tracking and monitoring gas flows easier than ever. Designed for use in the harshest industrial environments, eFlo allows for easy replacement of manual flow meters and seamlessly integrates into existing control systems.

| Integrated communication via Modbus over RS485 (RTU) and Ethernet (TCP/IP) |

| Pressure and temperature compensation for precise flow calculation |

| Flow Meter View software and mobile interface for configuration |

| Available with electronic valve, with or without control |

| Analog control and feedback for data acquisition |

| Direct and remote setpoint control |

| Built-in high/low flow alarms |

| Flow Totalizing |

| Compact footprint |

| Onboard datalogging |

| NIST-traceable calibration |

| Precision flow mesaurment |

| USB configuration tools |

| Mobile-friendly and web-based remote configuration |

| Flow calibration can be certified in use for CQI-9 requirements |

| Digital display: easy-to-use touch pad and optional touchscreen |

| SCADA integration: Current Flow, Totalized Flow, Setpoint, Cost Calculation |

| 1 1/4″ NPT |

| Gauge Display Adapter Kit Available |

| Acetylene | Helium |

| Air | Hydrogen |

| Ammonia | Hydrogen Chloride |

| Argon | Hydrogen Sulfide |

| Butane | Methane |

| Carbon Dioxide | Natural Gas |

| Carbon Monoxide | Neon |

| Chlorine | Nitrogen |

| Dissociated Ammonia | Nitrous Oxide |

| Endothermic Gas (C3H8) | Oxygen |

| Endothermic Gas (CH4) | Propane |

| Ethane | Sulfur Dioxide |

| Ethylene | Other (Contact SSi) |

| Exothermic Gas |

| Power Required: | 24VDC @ 400mA |

| Accuracy: | ±4% |

| Turndown Ratio: | 6:1 |

| Gas Temp. Limits: | 32°F to 150°F (0°C to 65.6°C) |

| Ambient Temp. Limits: | 32°F to 150°F (0°C to 65.6°C) |

| Flow Output Signal (Linear): | 4-20mA |

| Max. Output Signal Load: | 500 Ω |

| Input Control Signal (Linear): | 4-20mA |

| Response Time: | 1 – 10 seconds |

| Communications: | RS485, Ethernet, USB |

| Communications Protocol: | Modbus RTU, Modbus TCP, EtherNet/IP |

| Flow Meter Pressure Limits: | 5 psig max. |

| Pipe Fitting | 1 1/4″ NPT |

| Product Line | User Manual | Datasheet | Wiring | Other |

|---|---|---|---|---|

| eFlo 2.0 Standard Flow Meter | PDF | Online | eFlo Line Datasheet | Keypad Quick Start Guide | |

| Keypad Reference Guide | ||||

| Touchscreen Quick Start Guide | ||||

| Dimensions | ||||

| Footprint and Mounting Dimensions (pdf and dwg zip file) | ||||

| Safety Certification: Intertek – SGS | ||||

| General Info | Touchscreen Cleaning Procedure | |||

| Ethernet IP Studio 5000 Files (Requires Firmware 1.15+) |