- Phone:513.772.0060

- Address:7205 Edington Dr. Cincinnati, OH 45249

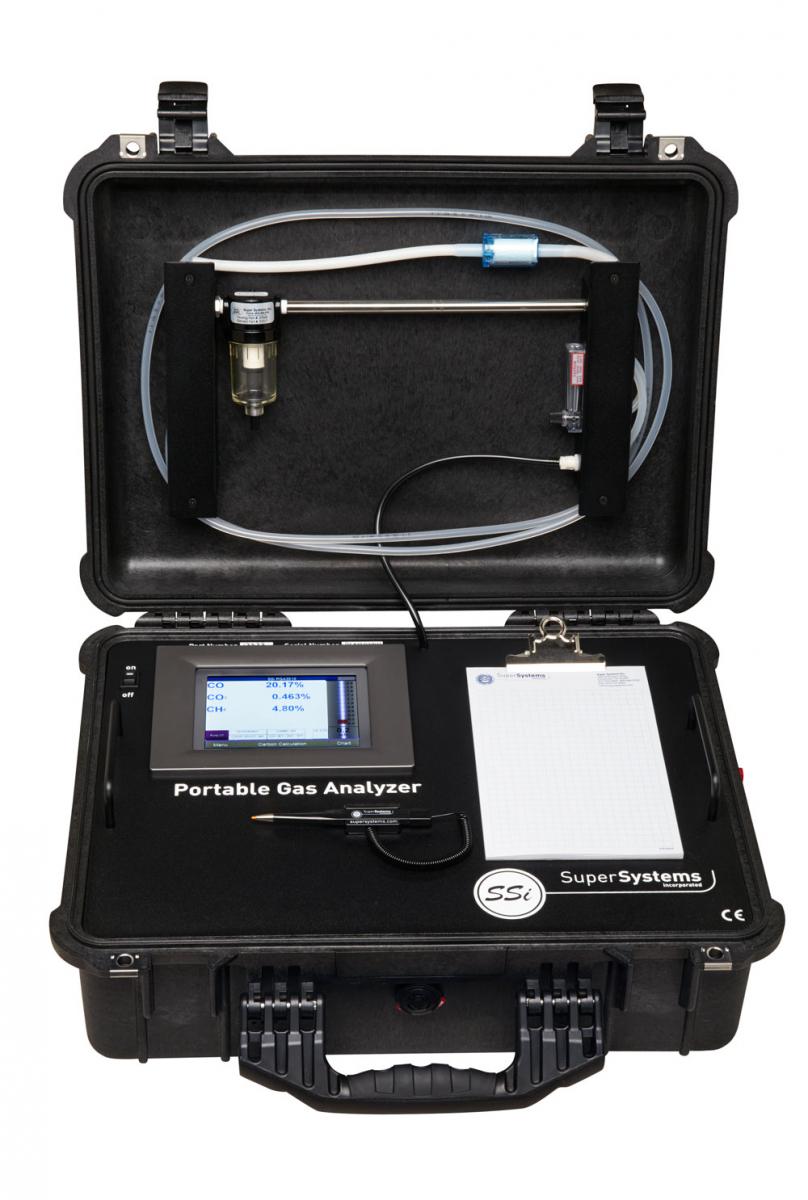

The portable gas analyzer can be used for the calculation of carbon in endothermic and nitrogen methanol based atmospheres with an input of temperature. This instrument meets CQI-9 requirements for daily generator and furnace atmosphere verifications.

| Accurate measurement of carbon based on gas composition |

| CQI-9 carbon potential verification device |

| Easy to operate |

| Built in sample pump |

| Battery operated |

| Easy to use on board calibration |

| Software utilities for printing charts |

| Field calibration for zero and span |

| Ethernet communications |

| Universal power (110 – 230 VAC) |

| Rechargeable battery |

| Available with ammonia-compatible design |

| Language editor |

| Data manager for downloading |

| Print charts and tabular data |

| Setup facility and furnace identifiers |

| Add notes when capturing data |

| Real time graphical display on PC |

| Export utilities |

| Backup data manager |

| PGA Utility Software for Configuration, Equipment, Language and Data Management with an Easy Interface |

| Sampling method | Extraction by internal pump (when necessary) |

| Measurement Method (CO, CO2, CH4) | Non-Dispersive Infrared (NDIR) |

| Measurement Method (O2) | Electrochemical |

| Measurement Method (H2) | Thermal Conductivity |

| Accuracy and repeatability | ± 1% of full scale |

| Recommended Factory Calibration Interval | Annual |

| Flow Meter | Inside case lid and also on-screen |

| AC Power Requirements | 90 to 230 VAC, 50 to 60 Hz, 60 Watts |

| DC Power Source | 12VDC rechargeable NiCd battery with Integral charger |

| Communications | Ethernet, USB(A), USB(B), RS485 Modbus |

| Data Storage | Continuous automatic data logging |

| Data Retrieval | XGA Viewer Software (included) or on-screen |

| Operating Temperature | 32° to 122° F (0° to 50° C) |

| External Dimensions | Approx. 16”H X 20”L X 8”D |

| Weight | Approx. 28 lbs. |

| CO: Carbon Monoxide | Range: 0 – 30% |

| CO2: Carbon Dioxide | Range: 0 – 2.0% Optional Range: 0 – 20.0% |

| CH4: Natural Gas/Methane | Range: 0 – 20% |

| Optional H2: Hydrogen | Range: 0 – 100% |

| Calculated % Carbon | Range: 0.1 – 2.00% |

| Suggested COF / PF factors | |

| Onboard Data Acquisition | |

| Enhanced with Nitriding/FNC Calculations | Carbon Potential (KC) Nitriding Potential (KN) |

| The effectiveness of the catalyst is measured by the CH4 content. Less than 0.5% is an indication of properly functioning catalyst. Higher concentrations indicate the necessity for either conditioning or replacement. |

| Measuring the level of CO in the carrier gas allows for correction of the % Carbon reading at the furnace. |

| Furnace atmosphere Carbon potential (% C) can be verified with the PGA 3510 |

| Measuring Carbon Monoxide (CO) allows for adjustment of the COF/PF parameters to fine tune the % Carbon calculation in the furnace |

| Measuring Carbon Monoxide (CO) and Carbon Dioxide (CO2) can show possible problems (i.e. sooting, water leaks, air leaks, and radiant tube leaks) |

| Too much free Methane (CH4) could be an early indication of a furnace problem |

| The carbon monoxide (CO) level in the furnace atmosphere indicates the effectiveness of the cracking of the methanol. Equilibrium of this reaction CH3OH –> CO + 2H2 is temperature dependent |

| Furnace atmosphere carbon potential (% C) can be verified with the PGA 3510 |

| Measuring carbon monoxide (CO) allows adjustment of the COF/PF parameters to fine tune the % Carbon calculation in the furnace |

| Measuring Carbon Monoxide (CO) and Carbon Dioxide (CO2) can show possible problems (i.e. sooting, water leaks, air leaks, and radiant tube leaks) |

| Product Line | User Manual | Datasheet | Wiring | Other |

|---|---|---|---|---|

| PGA3510 | PDF | Online | PGA 3510 Datasheet | ||

| PGA3500 (Legacy Product) | PDF | Online | |||

| XGA Viewer | ||||

| General Info | Atmosphere Measurement and Troubleshooting | |||

| Touchscreen Cleaning Procedure | ||||

| An Overview of Endothermic Generators |