- Phone:513.772.0060

- Address:7205 Edington Dr. Cincinnati, OH 45249

The RPS reads the signal from two oxygen probes located in the same furnace, automatically switching the output from the 9120 using the oxygen probe with the highest millivolt output. Additionally a manual selection of the probe is provided.

| Data logging using operator interface memory card |

| Operator interface trend line display |

| Indication showing which probe is being used for the % C calculation |

| Allows customer selection of probe “A” or “B”, or automatic selection |

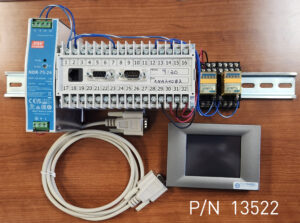

The Model 9120-RPS reads the signal from two oxygen probes located in the same furnace, automatically switching the output from the Model 9120 RPS to the probe with the highest millivolt output. It sends that probe’s output to the existing carbon controller to control the enriching gas being added to the furnace.

The probe millivolt “deviation band” and the “alarm delay” time are set using the operator interface. When connected per the electrical drawing, the Model 9120-RPS selects the probe with the highest millivolt output and sends that signal to the controller. As time passes and the other probe’s millivolt output becomes greater (depending on the deviation band), the Model 9120 RPS will switch the output from one probe to the other and send the “new” higher millivolt signal to the carbon controller.

The ” asterisks (*) ” on the operator interface display indicate which probe’s millivolts are being used by the furnace atmosphere controller. When the Model 9120-RPS switches the output from one probe to the other, it indicates a “deviation band” alarm condition, flashing an “A” on the operator interface. The “A” continues to flash until the probe’s output is back within the “deviation band”.

The operator can manually select the probe that he wishes to be used in the carbon calculation. If this feature is used, the 9120 RPS will use the operator-selected probe, and NOT switch from one probe to the other automatically.

| Product Line | User Manual | Datasheet | Wiring | Other |

|---|---|---|---|---|

| Redundant Probe System | PDF | Online | RPS Datasheet | ||

| Redundant Probe System w/ Touch Screen (RPSC) | PDF | Online | RPS Datasheet | ||

| General Info | Zirconia Sensor Theory | |||

| Carbon Sensor Troubleshooting | ||||

| Do it Right Advisory: Atmosphere Probes | ||||

| Do it Right: Maximize Product Quality |