- Phone:513.772.0060

- Address:7205 Edington Dr. Cincinnati, OH 45249

According to DOE studies – minimizing combustion air can deliver 35% savings. Checking and tuning air/fuel ratios is one of the simplest ways to get maximum efficiency out of fossil fuel fired process heat equipment.

| 3.5″ Color Touch Screen Display |

| Data Logging to Flash Memory |

| Burner “Out of Tune” Alarm |

| Ethernet |

| Multi-Sensor Inputs |

| Digital Input for High-Fire Notification |

| Burner Status Indication available remotely via web browser |

| Burner “not lit” alarm |

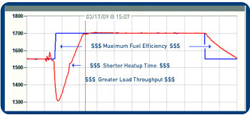

| Increased burner efficiency |

| Faster ramp to heat |

| Less fuel per load |

| Maximizes throughput |

| Reduce NOx & CO2 |

| Increased radiant tube life |

| Lowers flame temperature |

| Less heat for the load |

| More heat in the exhaust gases |

| Increase NOx |

| 10% excess air – yields 2% excess O2 in combustion gases |

| Sooting in radiant tubes |

| Lower flame temperature |

| Unburned fuel |

| Dangerous gas emissions (higher CO) |

| Process repeatability |

| Maximum throughput |

| Even distribution of heat |

| Longer radiant tube life |

| Product Line | User Manual | Datasheet | Wiring | Other |

|---|---|---|---|---|

| e-TRIM | PDF | Online | e-TRIM Datasheet | ||

| General Info | Zirconia Sensor Theory | |||

| Carbon Sensor Troubleshooting | ||||

| Do it Right Advisory: Atmosphere Probes | ||||

| Do it Right: Maximize Product Quality | ||||

| Combustion Efficiency |