- Phone:513.772.0060

- Address:7205 Edington Dr. Cincinnati, OH 45249

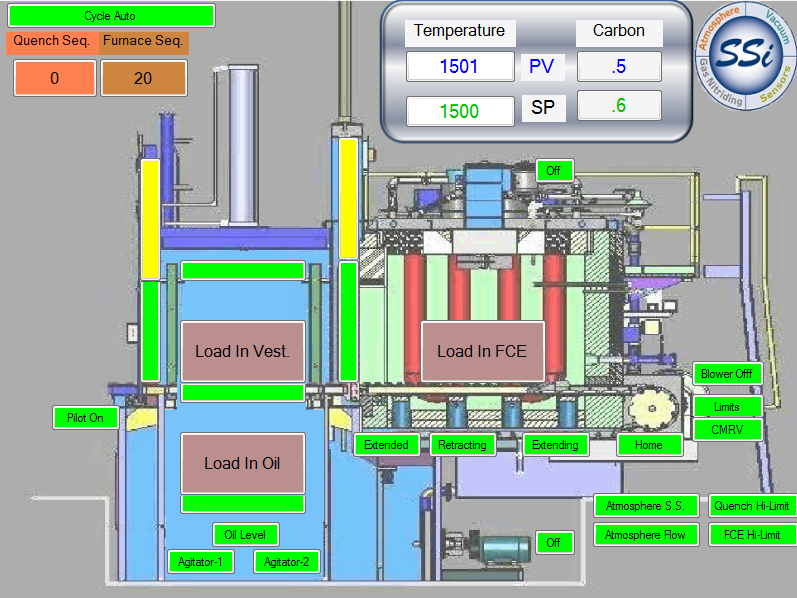

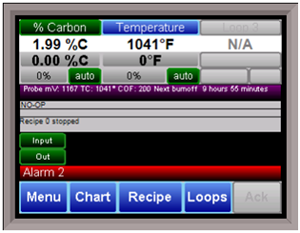

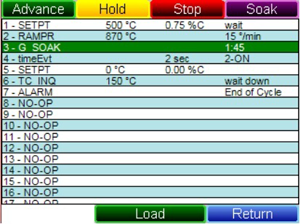

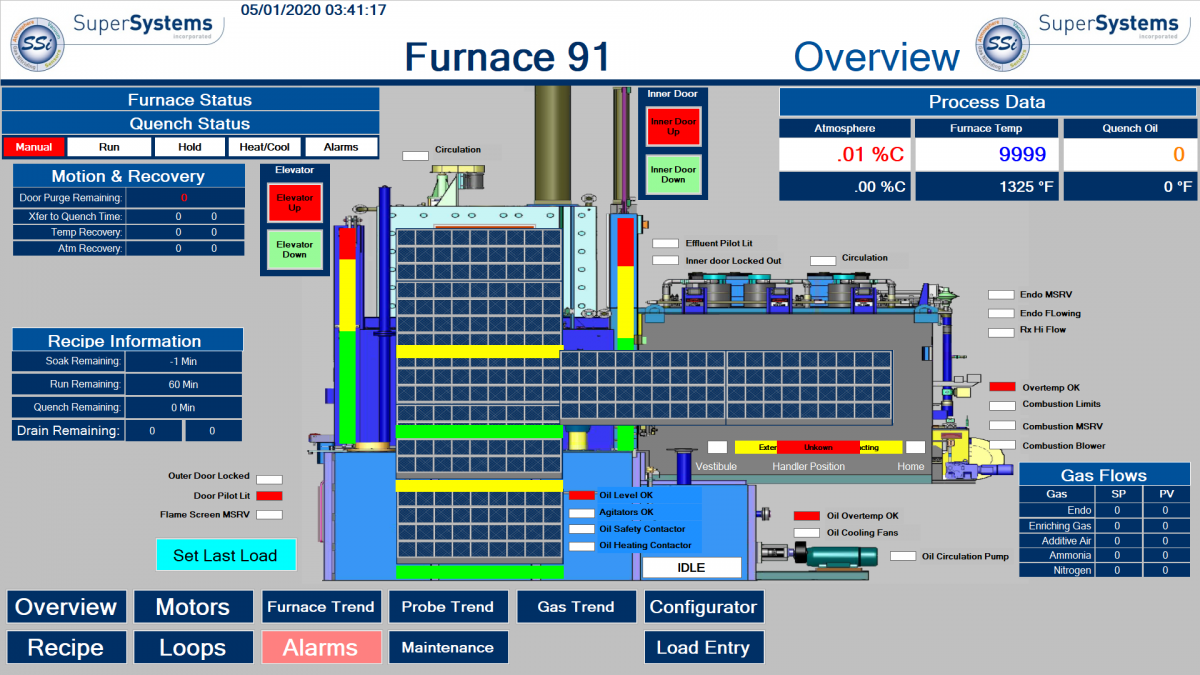

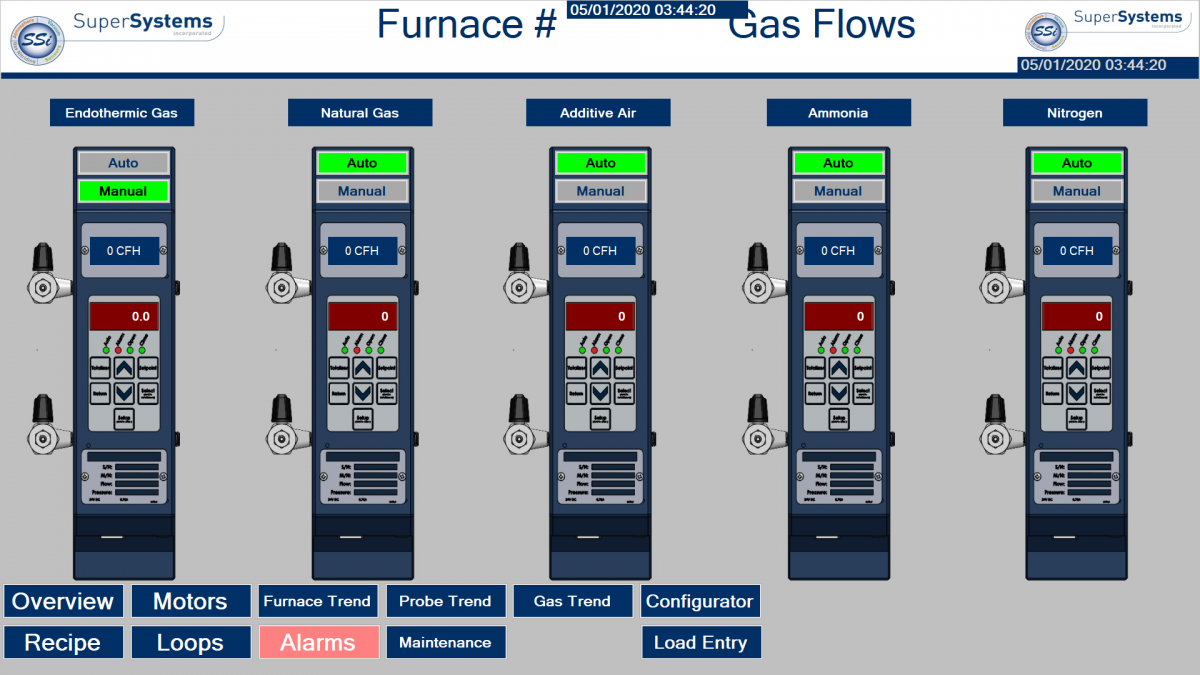

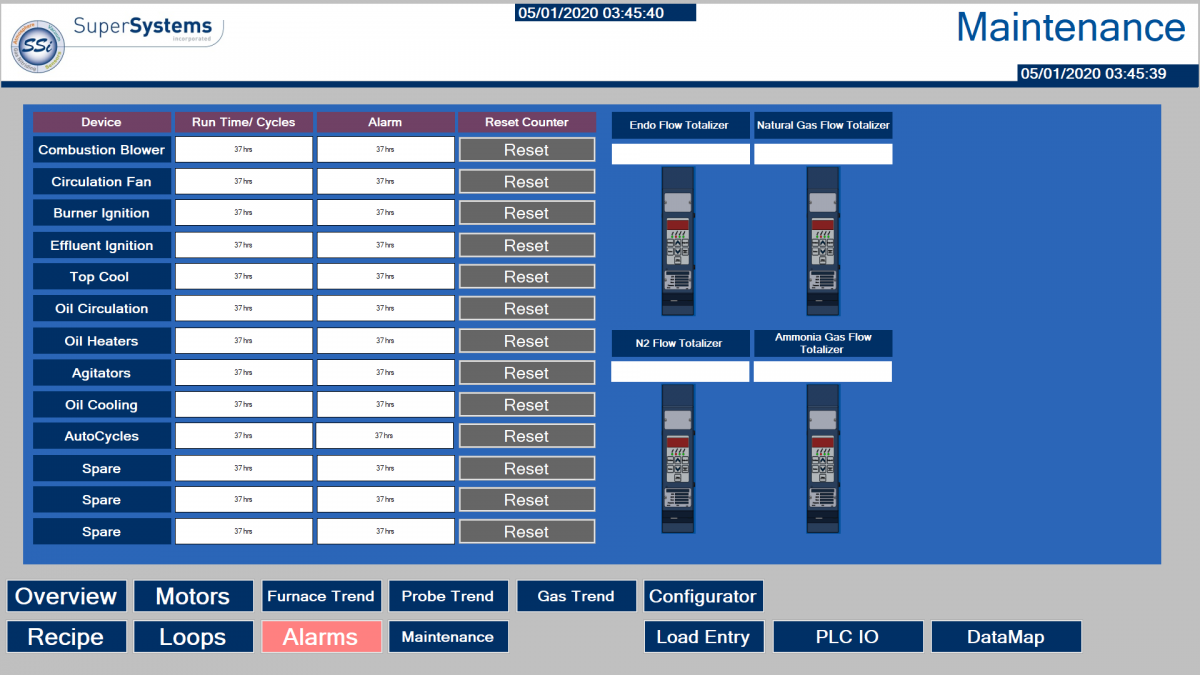

The powerful 9205 dual-loop controller provides comprehensive, intuitive batch atmosphere furnace PID control and programming. With cHMI, the 9205 becomes a comprehensive furnace HMI for operators and maintenance personnel. By integrating with SuperDATA (or other HMI/SCADA systems), management has a comprehensive view into the performance and utilization of their equipment.

| 16 PIDs via program opcode |

| 3 PID sets/loops with defined temperature switch point |

| T/C comparison with offset available for T/C checks |

| Multiple alarms assigned to individual relays or a single relay |

| Probe burnout & impedance test |

| “0.00″ setpoint deactivates control output |

| Band limits for each process variable |

| Remote setpoint for third input |

| Guarantee soak timer based on auxiliary load thermocouples |

| Software | Description |

|---|---|

| TS Manager | Data management for touch screen flashcard. Remote data viewer, historical data backup, SuperDATA integration. |

| Configurator | Remote setup and configuration of controller |

| Load History | View historical load information. |

| Control Loops | Three Loop PID controller Temperature, Temperature, Temperature Temperature and Carbon Potential Temperature and Dew Point Millivolt |

| Analog Inputs | Three |

| Analog Outputs | Expandable |

| Digital Inputs | Four |

| Digital Outputs | Eight relay outputs (Expandable to 16 or 32) |

| Communication Ports | Two (2) – RS232 Three (3) – RS485 Ethernet Allen Bradley DF1 |

| Display | 3.5″, 5.7″, 12.1″, 15″ and 17″ Color touch screen Video recorder with “NOTES” capability Removable storage media (948 months of data) PC interface with SuperDATA |

| Programmable | 300 12-Step Recipes or 300 24-Step Recipes |

| Events | User-Defined |

| Web Browser Enabled | Remote PC view with standard Web Browser |

| Mounting | DIN rail or sub-panel mounting |

| Power | 24 VDC |